Refurbished Brushes

Recondition Your Brush Rollers for top-performance

Welcome to IS Engineering Monforts Walzentechnik's Refurbished Brushes service page. Our refurbishing process transforms your old brush rollers into mint-new condition, ensuring top performance at a fraction of the price of new ones. With our expertise and meticulous attention to detail, we guarantee that our reconditioned brushes will deliver exceptional results while extending the life of your equipment.

Re-Garnishing Brush Rollers

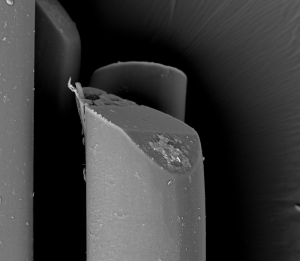

When your brush rollers reach the end of their rated lifespan due to wear, corrosion, or the inclusion of foreign objects, our re-garnishing service breathes new life into them. Our process involves replacing the worn-out bristles with new ones, ensuring a fully reconditioned, like-new roller brush.

The Refurbishing Process

- Send us your old brushes and Brush Rollers. We will inspect them thoroughly to determine the extent of wear and the necessary refurbishments.

- Reconditioning: Our expert artisans will remove the old bristles and recondition the brush body. This includes addressing any corrosion or damage to the roll body and ensuring it is in optimal condition for re-bristling.

- Re-Garnishing with New Bristles: We use only cotton cords for our brushes, making them much lighter and less dense than steel-corded brushes. This reduces the risk of product damage and prevents dirt and rust particles from getting trapped in the brush.

- Quality Inspection: Each refurbished brush undergoes a thorough inspection to ensure it meets our high quality and performance standards. We achieve a streak-free and uniform brushing result thanks to our unique bristling system.

- Dynamic Balancing: Fully electronic, dynamic balancing ensures the smooth running of your production machines and contributes significantly to a low-maintenance operation.

Advantages

- Lightweight Design: Cotton-corded brushes are lighter and less dense than steel-corded brushes, reducing the risk of product damage.

- Rust-Free: Avoid rust particles on your final product using cotton-corded brushes instead of steel cords.

- Uniform Brushing: Achieve a streak-free and uniform brushing result with our unique bristling system.

- Cost Savings: Save time and money by refurbishing your old brushes instead of purchasing new ones.

- Sustainability: Contribute to environmental sustainability by reusing your old brush rollers