Precision Brush Rollers for High-Speed Coating and Sanding

Enhance Flooring Quality and Efficiency with Precision Brush Rollers

At ISE Monforts, we specialize in creating high-performance brush rollers tailored for the flooring industry. Our brushes are engineered to provide superior results in various flooring applications, ensuring consistent quality and enhanced production efficiency.

Why Choose Our Brush Rollers?

Precision Engineering Our brush rollers are designed to meet the unique needs of flooring processing, ensuring optimal performance and high-quality finishes.

Reliable Quality We understand that the quality of the brush directly impacts the final appearance and durability of flooring materials. That’s why we ensure every brush we manufacture meets the highest standards of reliability and consistency.

Specialized Solutions for the Flooring Industry

We offer a comprehensive range of brush rollers designed for diverse flooring applications, ensuring each brush meets the precise requirements of your operations.

Applications:

- Sanding and Finishing

- Staining and Coating

- Deburring and Edge Smoothing

- Cleaning and Dust Removal

- Surface Preparation

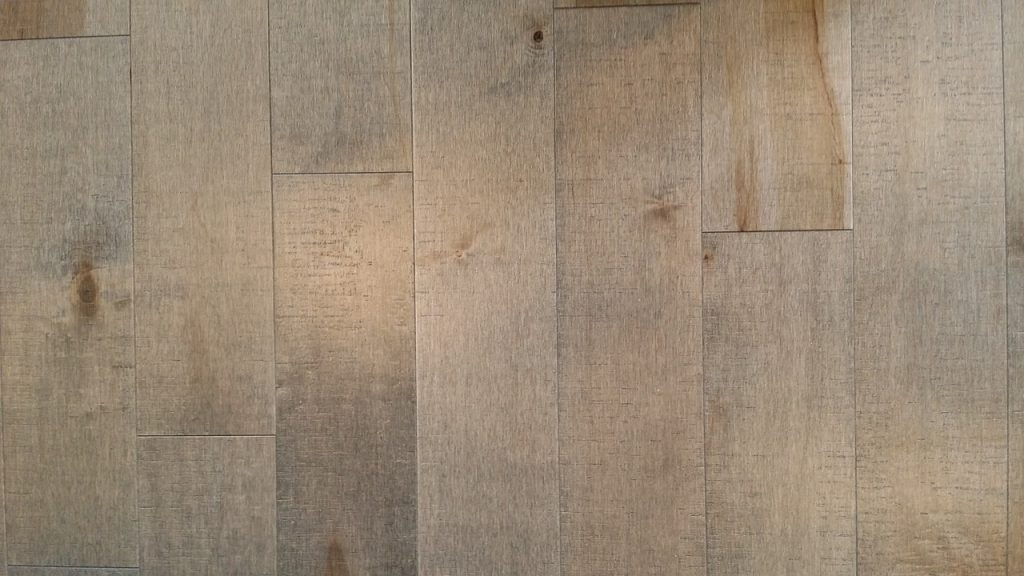

- Texturing and Patterning

How Brush Rollers are Used in Coating and Sanding

Sanding and Finishing:

- Uniform Sanding: Our brushes ensure even sanding of flooring surfaces, providing a smooth and consistent finish.

- Finishing Applications: Essential for applying finishes and coatings evenly, enhancing the durability and aesthetic appeal of flooring materials.

Staining and Coating:

- Consistent Staining: Brushes facilitate uniform application of stains and coatings, ensuring vibrant and consistent colors.

- Efficient Coating: Our brushes enable precise coating applications, enhancing the protective layer of flooring materials.

Deburring and Edge Smoothing:

- Edge Treatment: Effectively removes burrs and sharp edges, improving the safety and appearance of flooring components.

Cleaning and Dust Removal:

- Effective Cleaning: Brushes play a crucial role in removing dust and debris during processing, maintaining a clean environment and ensuring quality finishes.

Surface Preparation:

- Pre-Coating Preparation: Brushes prepare flooring surfaces for coating or staining, ensuring optimal adhesion and finish quality.

Texturing and Patterning:

- Aesthetic Enhancement: Our brushes can create unique textures and patterns on flooring surfaces, meeting diverse design preferences.

How to work with usSeamless Collaboration: Our 4-Step Partnership Process

Consultation

Custom Solution Design

Manufacturing and Quality Assurance

Delivery and Support

Engineered to Your Specific Needs

Whether you need a completely new brush design or a replication of your existing brushes, we tailor each roller brush to your specific needs. Our expertise helps you achieve highly-technical specifications, improved quality, and increased production output.

What We Offer:

- Custom Brush Design: Tailored solutions for your unique applications.

- Brush Refurbishment: Enhance the performance and lifespan of existing brushes through our refurbishment services.

- High-Quality Manufacturing: Consistent quality to ensure reliable and superior flooring processing results.

Optimize Your Flooring Processing Today

Contact us to learn how our specialized brush rollers can improve your flooring processing applications. Schedule a consultation to discuss your specific needs and receive personalized recommendations.